Because the material is directly impacted and collided with the target by high-speed airflow (including multiple rebound crushing with the crushing chamber wall), the crushing force is extremely large, and it can effectively crush most tough materials and fibrous materials. Equipped with a volute separator, the coarser materials can be continuously smashed, and the thickness is uniform after pulverization. Hexagonal or tooth-shaped targets can be selected to meet the pulverization requirements of different materials.

Pulverization can be carried out at lower than normal temperature, and is suitable for materials with heat sensitivity and low melting point.

Since the coarser material is continuously smashed, the thickness of the material after pulverization is uniform.

According to the nature and particle size of the raw materials, the hexagonal target or the toothed target is selected to meet the crushing requirements of different materials.

Simple structure, no moving parts, continuous production.

The noise is below 80 decibels.

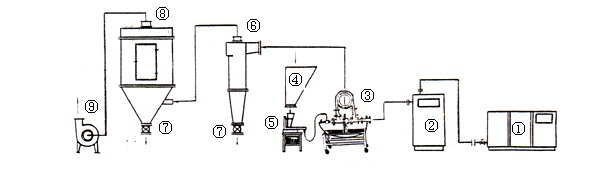

1. Air Compressor

2. Air Freeze Dryer

3. QBN450 Target Crusher

4. Silo

5. Electromagnetic Vibration Feeder

6. Cyclone Separator

7. Star Rotary Valve

8. Bag Catcher

9. Induced Fan

It is widely used in electrostatic copying powder, alginate, polyvinyl chloride, polypropylene, epoxy resin, ascaris mites, konjac flour, polyvinyl alcohol, licorice and other traditional Chinese medicines.

| Crushing Pressure |

0.6-0.8Mpa

|

Feed Particle size | Generally Less Than3mm | Net Weight |

250kg

|

| Feed Pressure |

0.3-0.5Mpa

|

Production Capacity | 10-100Kg/h | Air Consumption |

9-10m3/min

|

| Dimensions |

1490X1100X1020

|

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai