The pressure gas passes through the jet generated by the feeding injector, so that the crushed raw materials are sucked into the mixing chamber, and injected into the crushing cavity at the lower end of the "O" ring by the Venturi tube. Violent collision and friction occur to achieve crushing.

The pulverized fine powder is introduced into the primary classification chamber through the ascending pipe with the air flow. Due to the large centrifugal force, the coarse particles return to the pulverizing chamber through the descending pipe for cyclic pulverization. , which is discharged from the central outlet into the capture system.

QON type circulating tubular jet mill is suitable for ultra-fine grinding of dry brittle materials, and it is easy to obtain micron and submicron particles.

Relying on the self-grinding effect between objects, high-purity products can be obtained.

With the secondary internal classification structure, the fineness of the product and the uniform distribution of the particle size are improved.

The use of anti-wear lining increases the service life of the pulverizer and is suitable for the pulverization of hard materials.

The adiabatic expansion of the pressure gas produces a cooling effect, so that the pulverization is carried out at a low temperature, so it is especially suitable for the pulverization of low melting point and heat-sensitive materials.

The production process is carried out in a closed pipeline without dust flying.

The noise is less than 70 decibels and there is no vibration.

It can realize continuous production and automatic operation, and also play the effect of mixing and dispersing in the crushing process. By reforming the process conditions and local structure, drying, crushing and bag regeneration can be realized.

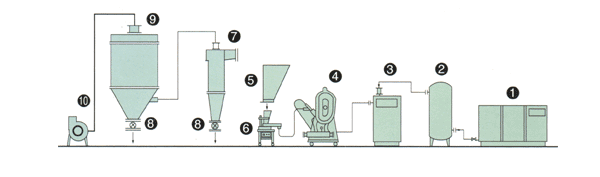

1. Air Compressor

2. Gas Tank

3. Refrigerated Compressed Air Dryer

4. QON Series Jet Mill

5. Vibration Silo

6. Screw Feeder

7. Cyclone Separator

8. Star Rotary Valve

9. Bag Catcher

10. Induced Fan

| Model (Parameters) |

Crushing Pressure (MPa)

|

Air Consumption (m3/min)

|

Production Capacity (kg/h)

|

Power (kw)

|

Dimensions (mm)

|

Weight (kg)

|

| QON75 |

0.6-0.9

|

6.2-9.6

|

30-150

|

65-75

|

836X600X1500

|

350

|

| QON100 |

0.6-0.9

|

13.5-20.6

|

100-500

|

110-135

|

1000X900X1870

|

650

|

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai