The electric vacuum feeder produced by our company is a new product developed on the basis of widely absorbing foreign similar products. conveying equipment.

It can automatically transport various materials to the hoppers of packaging machines, injection molding machines, pulverizers and other equipment, and can also directly transport mixed materials to mixers (such as V-type mixers, two-dimensional mixers, and three-dimensional mixers). etc.), it reduces the labor intensity of workers and solves the problem of dust spillage during feeding. It is the first choice for promoting clean and civilized production.

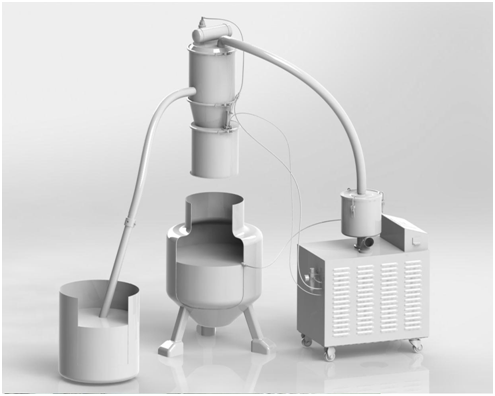

Electric vacuum feeder is composed of vacuum pump (no oil, no water), stainless steel suction nozzle, conveying hose, filter, compressed air blowback device, pneumatic discharge door device, vacuum hopper and automatic material level control device, etc. The whole system is reasonable in design and exquisite in manufacture.

The vortex air pump is used to pump air, so that the inlet of the suction nozzle and the whole system are in a certain negative pressure state. material separation.

The separated materials enter the receiving equipment.

Feeding - unloading is completed by the continuous opening and closing of the pneumatic reversing valve, and the opening and closing of the pneumatic reversing valve is controlled by the control center.

Vacuum conveying is a closed pipeline conveying. This conveying method can eliminate dust pollution, improve the working environment, reduce the pollution of the environment and personnel to materials, and improve the cleanliness. Because it is pipeline conveying, it occupies a small space and can complete powder in a narrow space. The material conveying makes the workspace beautiful and generous; especially it is not limited by the length and short distance. At the same time, the vacuum feeder can reduce labor intensity and improve work efficiency; it is the first choice for most powder material conveying methods.

|

Model |

Size(mm) |

Delivery Volume(kg/h) |

Power(kw) |

|

BJZ-1 |

220*830 |

150kg/h |

1.5 |

|

BJZ-2 |

220*830 |

300kg/h |

2. 2 |

|

BJZ-3 |

300*1010 |

500kg/h |

3 |

|

BJZ-4 |

300*1100 |

1200kg/h |

5.5 |

|

BJZ-5 |

420*1420 |

1800kg/h |

7.5 |

|

BJZ-6 |

600*1670 |

2500kg/h |

11 |

1. The operation process is carried out in a vacuum environment to avoid cross-contamination of materials with the outside world and operators

2. Reduce human and material resources and improve work efficiency

3. Strong conveying capacity, low energy consumption and good stability

4. Small footprint and wide application range

5. The equipment is easy to disassemble and install, the inner wall of the equipment is smooth, no gaps and no dead ends, and the workmanship is exquisite

6. The material is safe and reliable, medical grade 304 stainless steel, 316 can be customized

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai