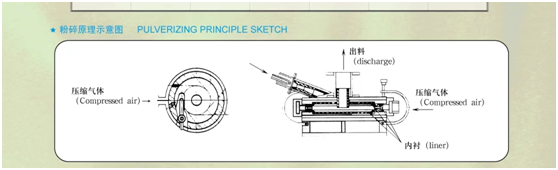

The compressed air passes through the nozzles evenly distributed around the pulverizing chamber and at a certain angle to the radial direction of the pulverizing chamber, converts pressure energy into velocity energy, and generates high-speed airflow, so that the powder material particles entering the pulverizing chamber continuously and uniformly through the feeding ejector , collide violently with each other, rub against each other and collide with the surface of the crushing chamber, so as to achieve the purpose of ultrafine crushing.

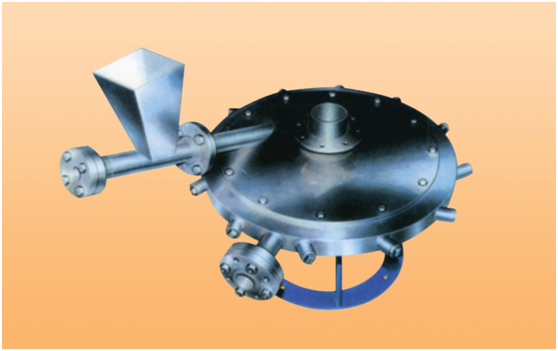

Ultrafine grinding for dry brittle materials

High-purity micron and sub-micron ultrafine particles can be obtained by self-grinding and pulverization relying on the interaction between powders.

Equipped with inner lining of steel, anti-stick and ceramic materials, it can solve the crushing of hard and sticky materials.

The adiabatic expansion of the compressed gas through the nozzle produces a Joule-Thomson cooling effect, so that the pulverization is carried out at a low temperature, which is especially suitable for the ultrafine pulverization of heat-sensitive and low melting point materials.

It can realize continuous production and automatic operation.

The machine is widely used in chemical, pesticide, light industry, food, medicine, non-metallic minerals, cosmetics and other industries and the crushing of various dry powder materials.

|

Parameter \ model |

QS50 |

QS100 |

QS200 |

QS300 |

QS350 |

QS600 |

QS1000 |

|

Air Consumption(m3/min) |

0.6-0.8 |

1.1-1.55 |

2.5-3 |

5.0-6.0 |

7.2-10.8 |

18-28 |

88-121 |

|

Production Capacity(Kg/h) |

0.5-2 |

2-10 |

10-30 |

10-75 |

30-150 |

200-600 |

1000-3000 |

|

Air Compressor Power(kW) |

7.5 |

13-15 |

22 |

37 |

65-75 |

132-250 |

600-750 |

|

Crushing Pressure(MPa) |

0.6-0.9 |

0.6-0.9 |

0.6-0.9 |

0.6-1.0 |

0.6-1.0 |

0.6-1.0 |

0.8-1.0 |

|

Product Granularity(um) |

Micron and Submicron Scale |

||||||

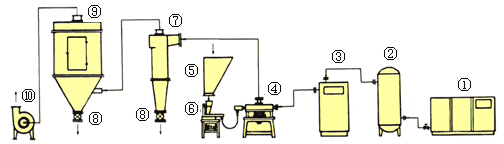

1. Air compressor 2. Air storage tank 3. Air freeze dryer 4. QS series jet mill 5. Silo

6. Electromagnetic vibration feeder 7. Cyclone catcher 8. Star rotary valve 9. Bag catcher 10. Induced draft fan

+86-21-64071149

+86-64481019

+86-64481022

No. 2094, Huan'an, Huanxing Village, Jinshan Industrial Zone, Jinshan District, Shanghai